Bearing Protection Systems for Critical Rotating Equipment

Designed to protect bearings from contamination, moisture ingress, and lubricant loss in demanding industrial environments.

Bearing Gard™ bearing protection systems are engineered to maintain effective bearing sealing under harsh operating conditions, reducing unplanned downtime, minimising maintenance intervention, and supporting consistent equipment performance across pumps, motors, gearboxes, and other critical rotating assets.

Engineered Bearing Protection for Safer, More Reliable Pump Operation

Process Containment Solutions (PCS) supplies Flowserve Bearing Gards™ as part of a holistic approach to pump protection, reliability, and compliance across mining, chemical processing, water treatment, and industrial manufacturing applications.

Bearing-related failures remain one of the most common causes of rotating equipment downtime in industrial pump systems. Flowserve Bearing Gards™ are engineered to protect rotating components, reduce safety risk, and support long-term equipment reliability in demanding operating environments.

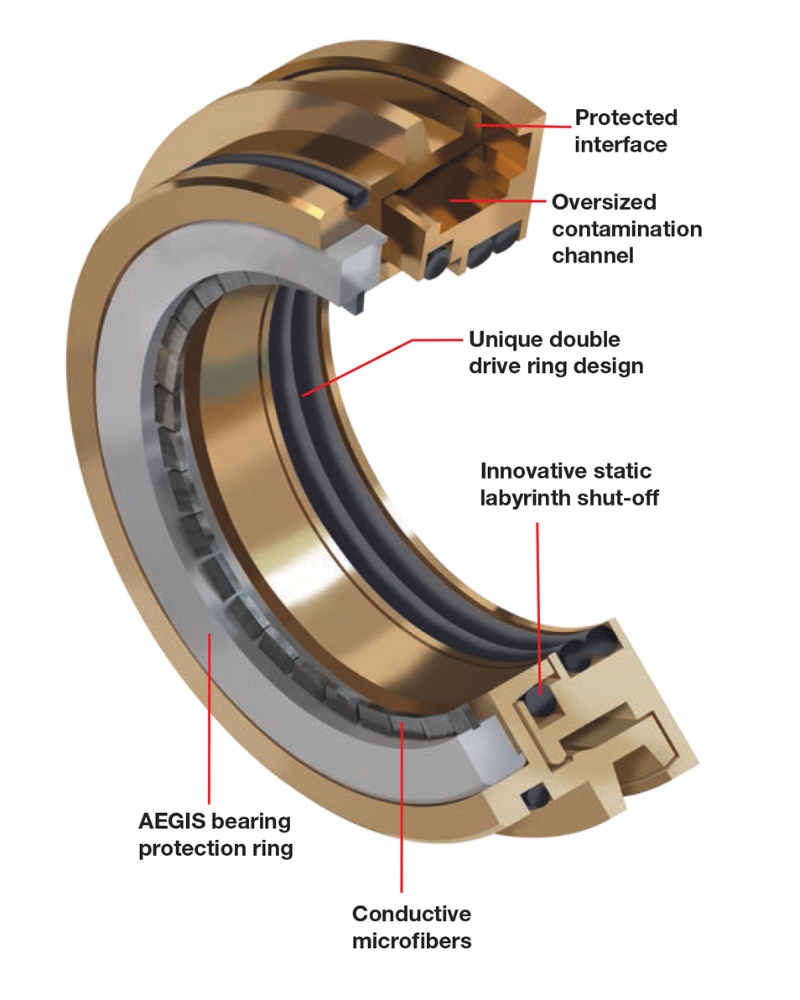

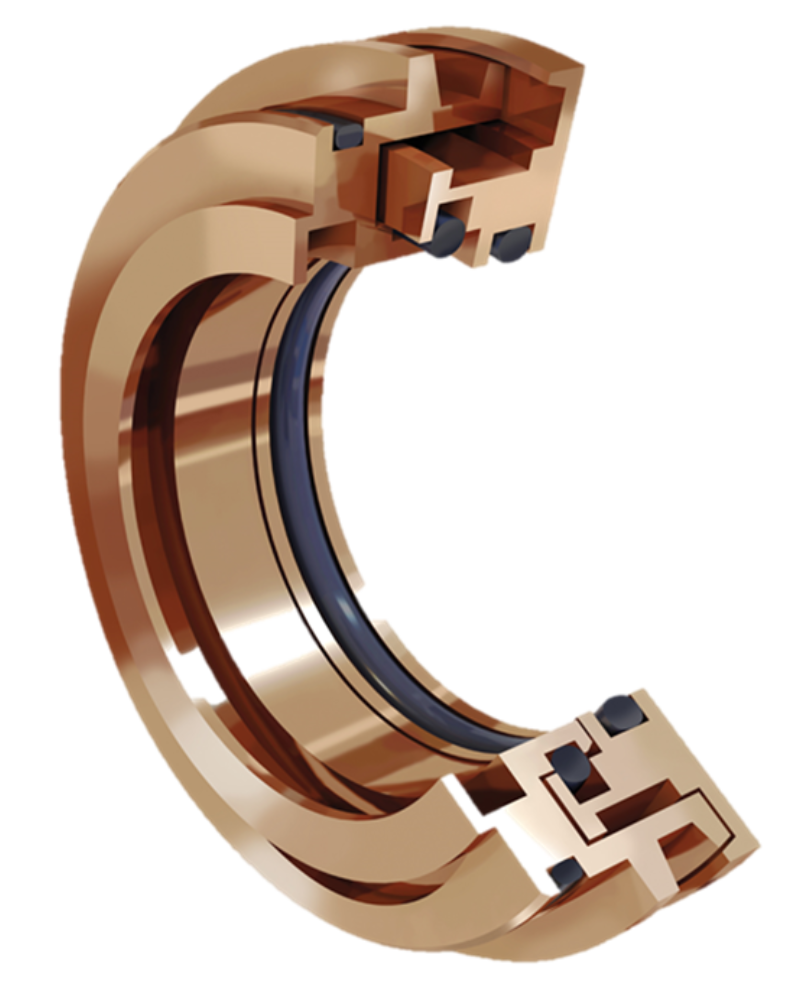

The Bearing Gard™ Bearing Isolator for Industrial Bearing Protection

The Bearing Gard™ Bearing Isolator provides robust protection against contaminants, helping keep the bearing housing clean while supporting efficient, reliable machinery operation and extended bearing service life.

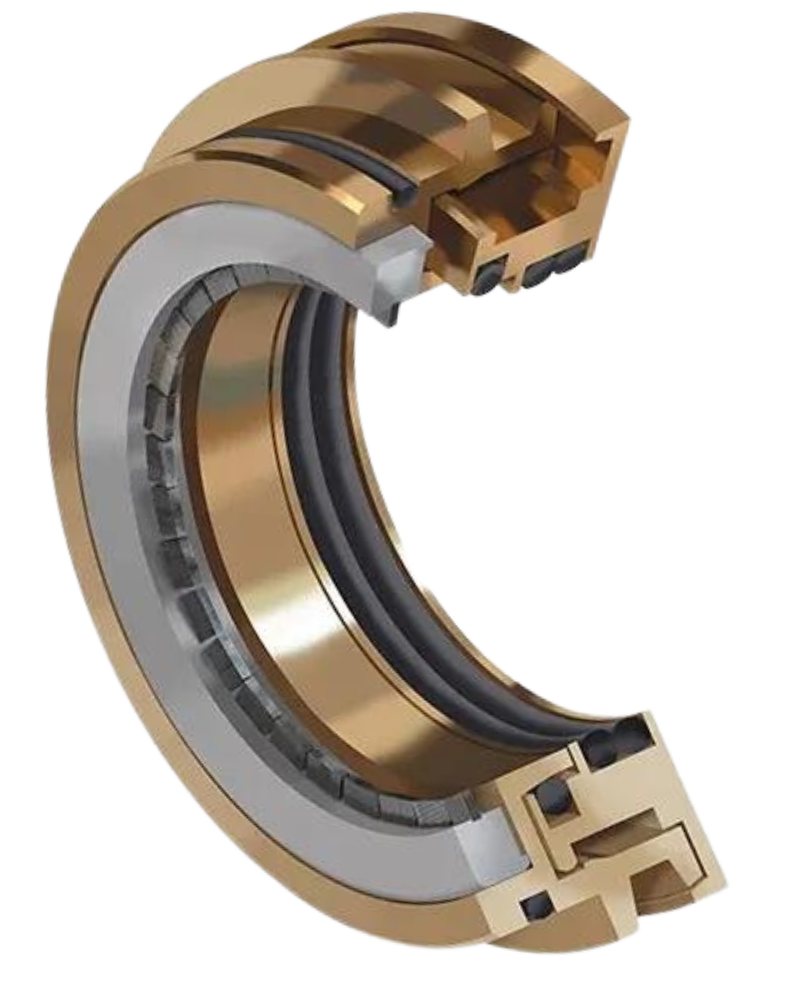

The Bearing Gard™ Bearing Isolator With Electrical Grounding

For applications where electrical discharge is a concern, the Bearing Gard™ bearing isolator combines sealing performance with electrical grounding to protect equipment from electrical damage.

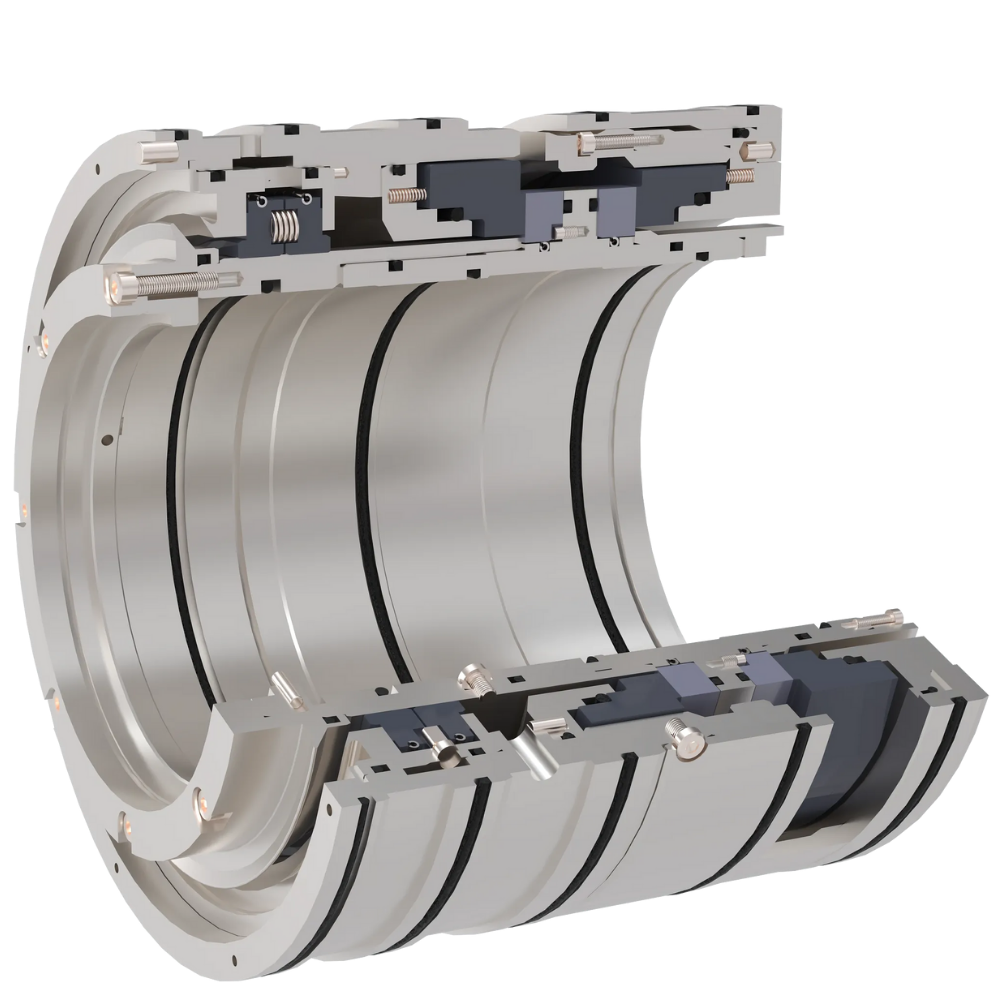

The Flowserve Aquapac Water‑Lubricated Compressor Seal

The Flowserve Aquapac water-lubricated compressor seal provides oil-free, non-contacting sealing for high-speed turbomachinery, improving reliability while eliminating contamination risk and auxiliary oil systems.

What Are Flowserve Bearing Guards?

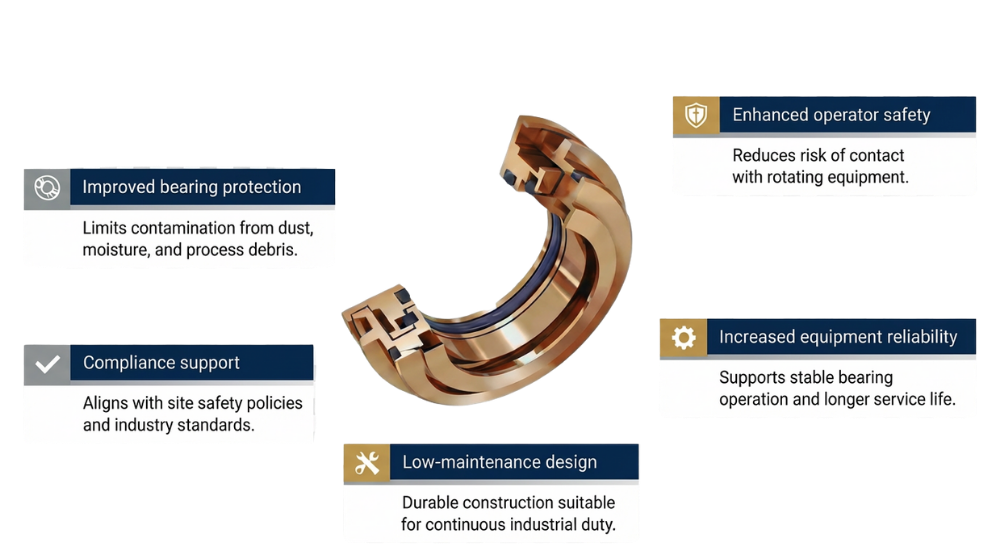

Flowserve bearing guards are precision-engineered protective covers designed to:

- Shield rotating pump components

- Prevent accidental contact with moving parts

- Reduce ingress of contaminants

- Support compliance with plant safety standards

Installed at bearing housings, these guards play a critical role in both equipment protection and operator safety, particularly in high-speed or continuous-duty pump applications.

Why Bearing Gard™ Selection Matters

Unprotected or poorly guarded bearings expose plants to multiple risks, including:

-

Increased wear due to dust, moisture, or debris ingress

-

Elevated safety hazards around rotating shafts

-

Non-compliance with site or regulatory safety requirements

-

Unplanned downtime caused by bearing failure

Correctly specified Bearing Gards™ help extend bearing life, stabilise operation, and reduce maintenance intervention, especially in harsh or abrasive environments.

Typical Applications

Flowserve Bearing Gards™ are commonly used on pumps operating in:

-

Mining slurry and dewatering systems

-

Chemical and petrochemical process plants

-

Water and wastewater treatment facilities

-

Industrial process water circulation

-

Manufacturing and power generation environments

These applications demand robust guarding solutions that perform reliably under vibration, load variation, and environmental exposure.

Maximised Equipment Reliability With Flowserve's Advanced Bearing Gards™

Flowserve bearing guards are designed to protect rotating equipment by limiting the ingress of dust, moisture, and process contaminants. By stabilising bearing operating conditions, they help reduce wear, extend service life, and support consistent equipment reliability, while also contributing to safer operation around rotating machinery.

Materials and Design Options

Flowserve bearing guards are available in configurations suited to a wide range of operating conditions, including:

-

Metallic and non-metallic guard options

-

Designs compatible with standard Flowserve pump ranges

-

Configurations suited to corrosive or abrasive environments

-

Guards designed for easy inspection and maintenance access

PCS assists clients with correct selection based on pump type, operating speed, environment, and safety requirements.

PCS Approach to Bearing Guard Specification

PCS does not promote generic or one-size-fits-all solutions. Bearing guard selection is assessed in context with the full pumping system, including:

-

Pump design and shaft configuration

-

Operating speed and duty cycle

-

Environmental exposure (dust, moisture, chemicals)

-

Maintenance access requirements

-

Plant safety and compliance obligations

This ensures bearing guards support long-term reliability rather than short-term fixes.

Why Choose Process Containment Solutions?

PCS combines OEM-aligned products with application-driven engineering support, ensuring that Flowserve bearing guards are specified, installed, and supported correctly.

Clients benefit from:

-

Technical product knowledge

-

Application-specific guidance

-

Support across the equipment lifecycle

-

Responsive after-sales service

Discuss Flowserve Durco Pump Requirements with PCS

Selecting a chemical process pump requires more than matching flow and pressure values.

If you are assessing Flowserve Durco Chemical Process Pumps for a new installation, replacement, or system upgrade, PCS can provide application-specific technical guidance based on your process conditions.