Titan Lobe Pumps

Designed to deliver hygienic, low-shear fluid transfer with consistent performance, precise flow control, and reliable operation in critical industrial process environments.

Titan lobe pumps are engineered for demanding hygienic and industrial process applications, delivering controlled, low-shear fluid transfer for viscous, sensitive, or shear-critical media across food, beverage, pharmaceutical, and chemical processing environments.

Engineered Positive Displacement Pumps for Precise, Low-Shear Fluid Handling

Titan lobe pumps are positive displacement rotary pumps designed for applications where product integrity, hygienic handling, and controlled flow are critical. Their gentle pumping action makes them suitable for shear-sensitive, viscous, and solids-laden fluids across food, pharmaceutical, chemical, and industrial processing environments.

Process Containment Solutions (PCS) supplies and supports Titan lobe pumps as part of an application-driven approach to fluid handling… ensuring each pump is correctly selected for duty conditions, fluid properties, and operational requirements.

Advantages of Titan Lobe Pumps in Industrial Systems

When correctly specified, Titan lobe pumps offer measurable operational benefits:

-

Gentle handling of shear-sensitive fluids

-

Accurate and repeatable flow rates

-

Stable performance under fluctuating pressures

-

Reduced risk of product damage or separation

-

Long service life with correct maintenance

Incorrect selection, such as overspeeding, unsuitable materials, or improper clearances, can lead to wear, inefficiency, or contamination risk. PCS prioritises correct specification from the outset.

Materials and Hygienic Options

Titan lobe pumps are available in a range of materials and configurations to suit both hygienic and industrial duties, including:

-

Stainless steel constructions for hygienic services

-

Elastomer and seal options matched to process media

-

Designs compatible with CIP (Clean-in-Place) regimes

-

Configurations suitable for corrosive or temperature-sensitive fluids

Material selection is confirmed based on chemical compatibility and cleaning requirements.

Typical Applications for Titan Lobe Pumps

Titan lobe pumps are widely used in processes where clean transfer, controlled flow, and product protection are required.

Common applications include:

-

Food and beverage processing

-

Pharmaceutical and cosmetic manufacturing

-

Chemical processing and batching

-

Polymer, resin, and adhesive handling

-

Paints, coatings, and specialty fluids

-

Industrial process fluids requiring low shear

Each application is assessed against actual process conditions, including viscosity, temperature, solids content, and cleaning requirements.

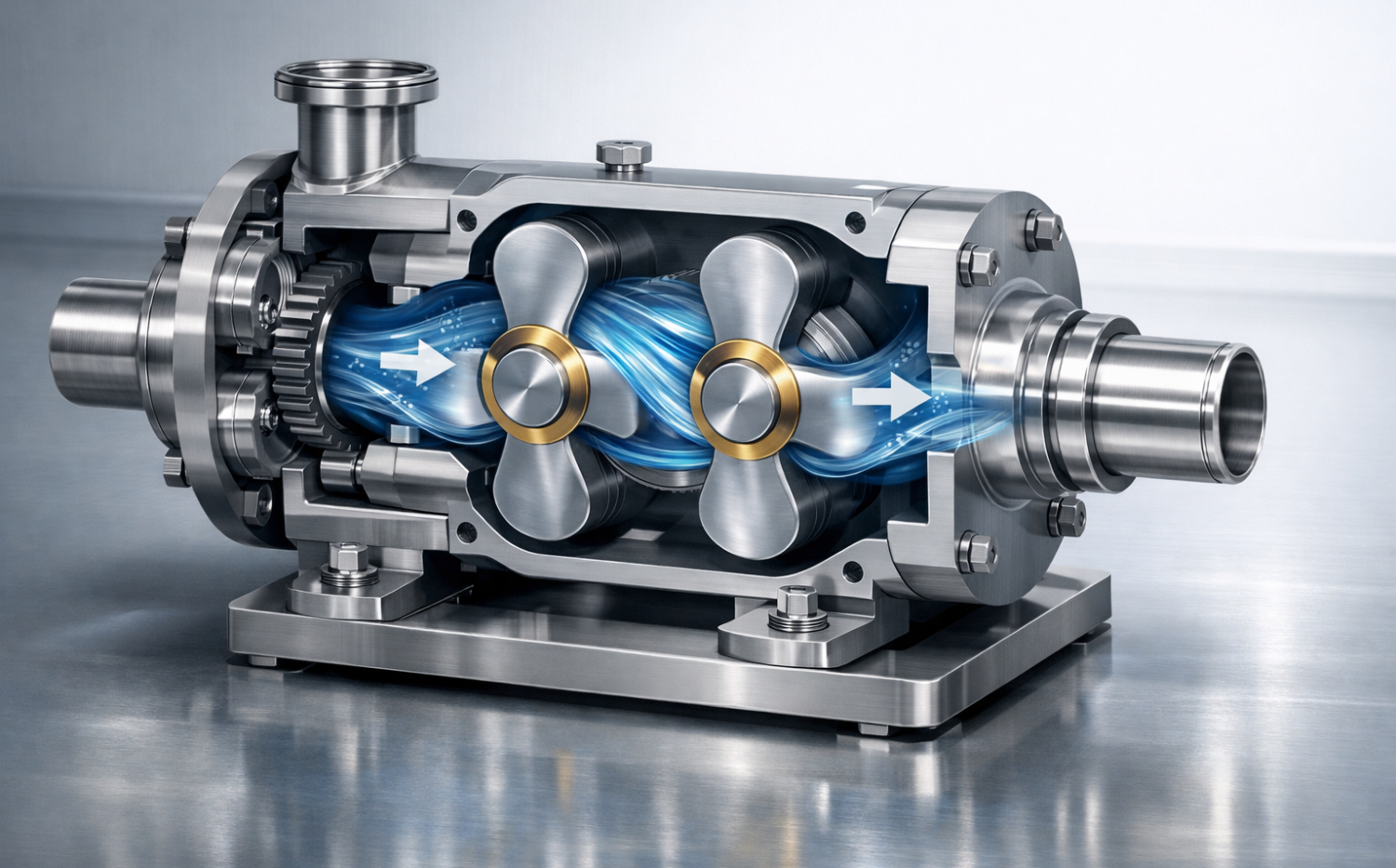

How Titan Lobe Pumps Work

Not every block plant requires full automation from day one. The most successful African producers invest in the right level of automation for their current demand, while retaining the ability to scale.

| Section | Description |

|---|---|

| How Titan Lobe Pumps Work | Titan lobe pumps use non-contacting, counter-rotating lobes to move fluid through the pump chamber. As the lobes rotate, fluid is trapped in cavities and transferred from the inlet to the discharge without significant shear or pulsation. |

| Operating Principle Benefits |

Correct lobe geometry and internal clearances are essential to achieving reliable performance and service life. |

| Key Features |

PCS evaluates each installation to confirm material compatibility, speed selection, and operating limits, reducing the risk of premature wear or efficiency loss. |

Why Correct Lobe Pump Selection Matters

Lobe pumps are precision machines. Performance and reliability depend on:

-

Correct speed and flow selection

-

Appropriate lobe geometry

-

Accurate material compatibility

-

Alignment with cleaning and hygiene protocols

PCS does not promote one-size-fits-all solutions. Each Titan lobe pump is selected based on process conditions, risk profile, and lifecycle performance requirements.

Speak to PCS About Titan Lobe Pumps

If your application requires controlled, low-shear fluid transfer with reliable long-term performance, PCS can assist with the correct Titan lobe pump solution. Contact Process Containment Solutions to discuss your application requirements or to request technical guidance.

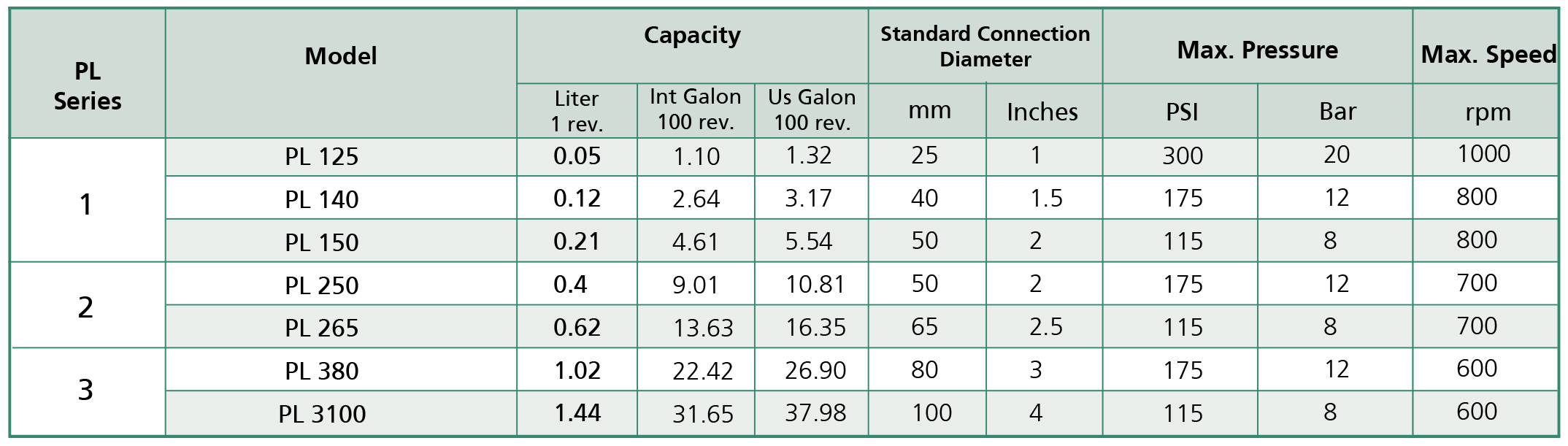

Meticulously Designed To Address The Diverse Needs Of Hygienic Pumping Applications

Whether in the realms of food, dairy, beverage, pharmaceuticals, or other industries where the utmost cleanliness is paramount, our Titan PL Series Lobe pumps excel. Designed with precision and constructed from stainless steel, these pumps embody resilience against the fluids they handle.

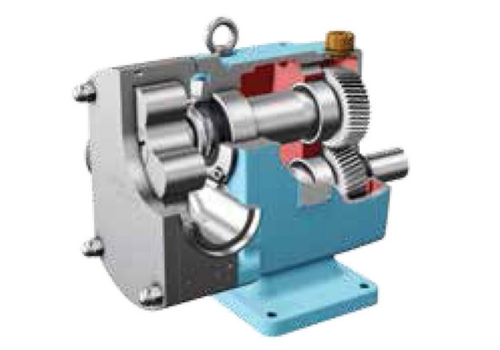

Rotary Lobe Pump

Engineered to cater to a diverse range of hygienic pumping applications.

Designed with precision and constructed from stainless steel, these pumps embody resilience against the fluids they handle.

Their robustness ensures seamless operation even in the most demanding environments, where hygiene and resistance to liquids are non-negotiable.

Features and Advantages

- Three kind of gear boxes with seven kinds of pump models.

- Heating / Cooling jackets easy to fit on the front cover and/or rotor casing.

- The inlet/outlet connection ports are monoblock with casing. It is hygienic due to not welding.

- Single seal which can be modified to a double type (flushing) with a minimum of additional part.

- Horizontal ports which can be fitted vertical simply.

- The offered rotor shaft as down as standard, can be easily change to up.

- It is suitable to drive clockwise / counter clockwise direction (both).

- The inlet / outlet connection ports can be offered with DIN 11851, tri clamp or flange.

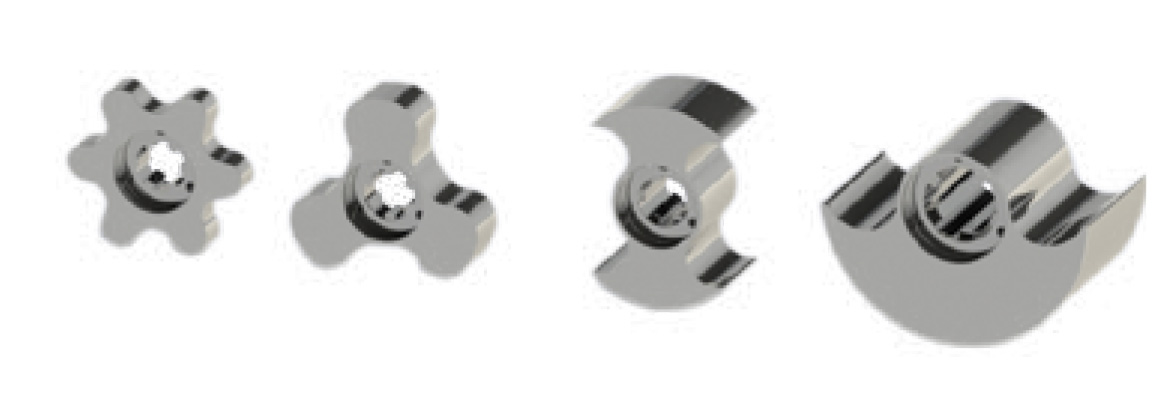

- The lobe type can be offered with single wing, bi-wing, tri-lobe and multi lobe according to application.

- The clearances can be setted according to viscosity.

- The inlet port can be rectangular for high viscosity applications to feed well.