Hippo Slurry Pumps

The design of Hippo Slurry Pumps prioritises durability, wear resistance, and controlled solids handling.

Heavy-duty submersible slurry pumps engineered for continuous operation in abrasive, solids-laden environments, delivering controlled performance, reliability, and extended service life in demanding mining and mineral processing applications.

Heavy Duty Slurry Pumps for Mining and Industrial Applications

Heavy duty slurry pumps are engineered to handle abrasive, high-solids, and high-density slurries in some of the most demanding industrial environments. These pumps play a critical role in maintaining uptime across mining, mineral processing, and heavy industrial operations where process interruptions carry significant operational and financial risk.

What Is a Heavy Duty Slurry Pump?

A heavy duty slurry pump is a centrifugal pump specifically designed to transport slurries containing abrasive solids, coarse particles, and corrosive media. Unlike standard centrifugal pumps, slurry pumps are built with:

-

Reinforced casings

-

Heavy-wall wear components

-

Hardened or elastomer-lined internals

-

Shaft and bearing assemblies designed for high radial loads

These features allow the pump to operate reliably under high wear, high impact, and variable flow conditions.

Typical Applications for Heavy Duty Slurry Pumps

PCS heavy duty slurry pumps are commonly specified for:

-

Mining slurry transfer

-

Tailings handling

-

Mineral processing circuits

-

Thickener underflow

-

Mill discharge and cyclone feed

-

Ash handling in power generation

-

Industrial effluent with suspended solids

Each application presents unique challenges related to particle size, slurry density, abrasiveness, and chemical composition, making correct pump selection essential.

Local Technical Support and Lifecycle Services

PCS provides local technical support across South Africa, supporting both new installations and existing slurry pump systems. Local support ensures faster response times, reduced downtime risk, and continuity of operations in critical environments.

Support services include:

-

Pump selection and system evaluation

-

Wear analysis and performance assessment

-

Spares supply and component replacement

-

Maintenance and repair support

-

Technical guidance for uptime optimisation

Incorrect slurry pump selection can result in:

-

Accelerated wear and frequent failures

-

Excessive power consumption

-

Seal and bearing damage

-

Increased unplanned downtime

PCS prioritises correct specification from the outset to protect equipment integrity, operational continuity, and maintenance budgets.

The Complete Hippo Slurry Pump Line-Up

Below is the PCS-supported full Hippo ® range, each engineered for a specific duty profile and mining application.

Submersible Top Suction Pumps

Ideal for Shallow Sumps and Fast-Settling Solids

Designed to pull slurry from the top layer, these pumps prevent floating slurry build-up and maintain continuous operation in:

- Wash-down sumps

- Plant cleaning pits

- Process water reclaim systems

- Light to medium-density slurry applications

Key Benefits:

- Easy installation and retrieval

- Suitable for sump cleaning and desilting

- Reduced risk of cavitation in turbulent sumps

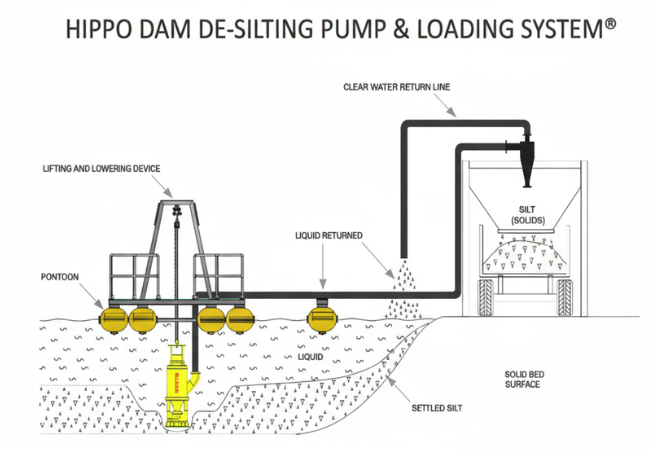

Bottom Suction Submersible Pumps

Maximum Solids Intake for Sump Desludging

Purpose-built for rapid-settling, high-density solids located at sump bottoms or dam floors.

Perfect for:

- Thickener underflow pits

- Settling pond extraction

- Deep-mud applications

- Tailings dam recovery

Key Benefits:

- Aggressive solids pickup

- High chrome wet-end durability

- Optimised for dense, abrasive slurry

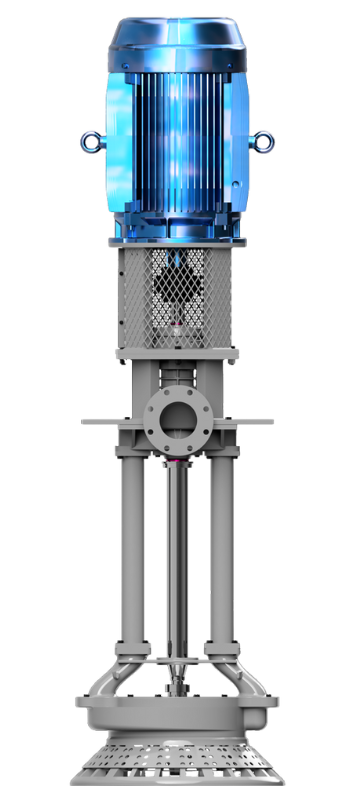

Bottom Discharge Slurry Vertical Spindle Pumps

Ideal for Shallow Sumps and Fast-Settling Solids

Designed to pull slurry from the top layer, these pumps prevent floating slurry build-up and maintain continuous operation in:

- Wash-down sumps

- Plant cleaning pits

- Process water reclaim systems

- Light to medium-density slurry applications

Key Benefits:

- Easy installation and retrieval

- Suitable for sump cleaning and desilting

- Reduced risk of cavitation in turbulent sumps

Bottom Suction Slurry Verticle Spindle Pumps

The Preferred Design for Quick-Settling Solids

With an external agitator and bottom suction intake, these pumps excel in heavy, fast-settling solids where constant agitation is required.

Used extensively in:

-

Platinum & chrome mining

-

Gold plant sumps

-

Dewatering of loaded solids

-

Thick, abrasive slurry

Key Benefits:

-

Prevents solids settlement

-

Continuous run-dry capability

-

Exceptional wear resistance

Vertical Spindle Vortex Top Suction Pumps

Top Suction with Vortex Flow for Reduced Blockage

A vortex-style impeller provides non-clog operation in slurries with:

-

High-fibrous content

-

Oversized solids

- Mixed industrial waste streams

Ideal for:

-

Process water systems

-

Clarifier sludge

-

Industrial effluent with solids

Key Benefits:

-

Non-clog vortex design

-

Handles large particle sizes

- Smooth hydraulic performance

Engineered for Harsh, High-Abrasion Slurry Applications

Hippo® Slurry Pumps are built to deliver consistent throughput, long wear life, and reliable uptime in deep sumps, tailings dams, mill circuit sumps, settling ponds, and corrosive slurry environments. These pumps are designed specifically for the extreme conditions found in gold, platinum, coal, chrome, copper, and cobalt mining operations.

Mining operations across North West Province, Limpopo, Zambia, and the DRC require pumping systems capable of handling aggressive and unpredictable slurry conditions.

North West Province

Rustenburg, Brits, Klerksdorp

-

Platinum, chrome & gold operations

-

Deep sump dewatering

-

Mill circuit slurry handling

Limpopo Province

Mogalakwena, Lephalale, Musina

- Nickel, copper & coal

- Settling dam pumping

- Process plant sumps

-

Zambia

Kitwe, Chingola, Mufulira

-

Copper tailings

-

High-density process slurries

-

Thickener underflow hauling

DRC

Katanga & Lubumbashi

-

Corrosive, acidic slurries

-

High solids density

-

Aggressive abrasive duty

Key Design Features and Performance Benefits

Heavy duty slurry pumps supplied by PCS are selected to deliver long service life and stable hydraulic performance under severe operating conditions.

Core Performance Advantages:

-

High resistance to abrasive wear

-

Stable performance at high solids concentrations

-

Robust bearing assemblies for extended MTBF

-

Replaceable wear components to reduce lifecycle cost

-

Configurations suitable for high-pressure duties

Correct hydraulic sizing and material selection are critical. Oversizing, incorrect impeller selection, or unsuitable materials can significantly increase wear rates and energy consumption.

Material Options for Abrasive Slurry Handling

Material selection has a direct impact on pump lifespan and maintenance frequency. PCS supports material selection based on slurry characteristics and operating conditions, including:

-

High-chrome white iron for extreme abrasion

-

Elastomer linings for fine or chemically aggressive slurries

-

Corrosion-resistant alloys where chemical attack is present

-

Shaft sleeve and seal material options matched to service conditions

Material compatibility is assessed to balance wear life, efficiency, and total cost of ownership.