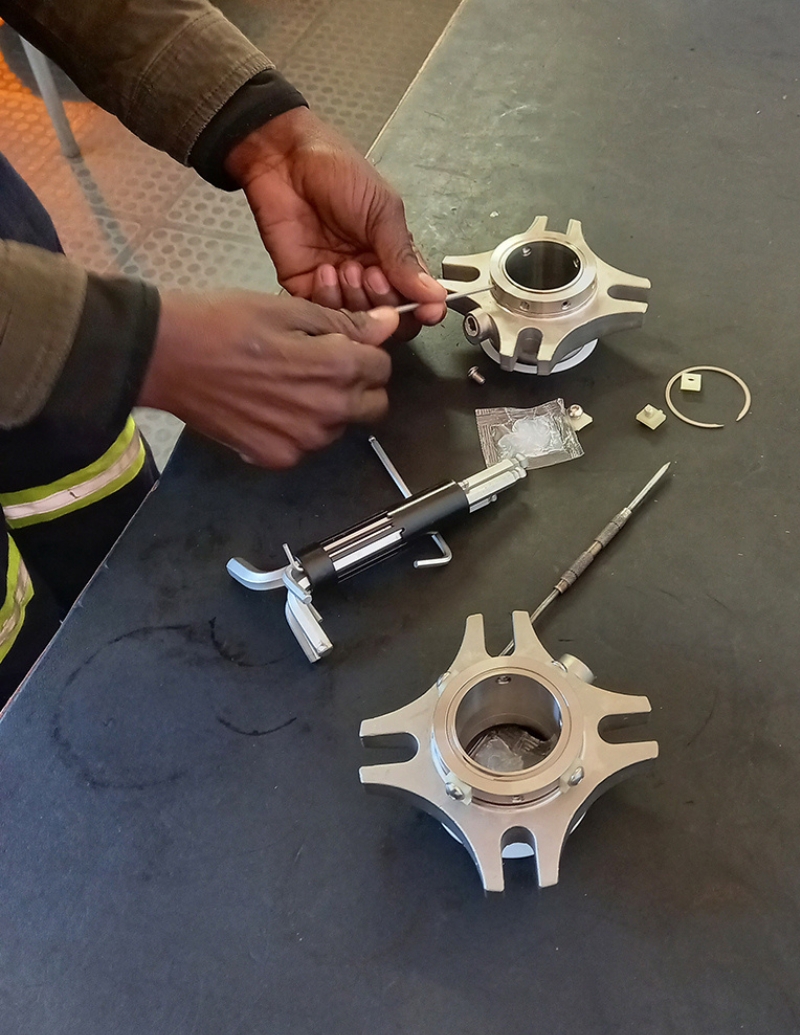

Mechanical Seal Repairs

Restores critical mechanical seals to OEM-aligned condition, reducing leakage risk and unplanned downtime.

Precision repair and restoration of mechanical sealing systems, combining detailed inspection, controlled workmanship, and component-level expertise to ensure sealing integrity, operational safety, and long-term reliability in critical rotating equipment.

Engineered Repairs for Reliability, Safety, and Extended Seal Life

Mechanical seals operate at the centre of process reliability. When a seal fails, the impact is immediate… unplanned downtime, safety exposure, and increased maintenance cost. Our repair approach focuses on restoring seal performance to specification, supporting safe operation, and extending service life in demanding environments. Professional mechanical seal repair services for industrial applications where correct refurbishment, controlled tolerances, and operating reliability are critical.

Applications We Commonly Support

PCS mechanical seal repair services are commonly applied to seals used in:

-

Slurry and abrasive pumping systems

-

Chemical dosing and transfer pumps

-

Process water and effluent handling

-

Hydrocarbon and solvent circulation

-

High-duty industrial process pumps

Each application is reviewed individually to confirm repair suitability and service expectations.

Require Technical Assistance?

Get In Touch With Us 24/7

Our Mechanical Seal Repair Process

PCS follows a structured, engineering-driven repair methodology designed to reduce repeat filures and restore mechanical seal performace to specification.

| PROCESS STAGE | KEY ACTIVITIES |

|---|---|

| 1. Incoming Inspection and Assessment |

|

| 2. Root-Cause Evaluation |

|

| 3. Precision Refurbishment |

|

| 4. Assembly and Quality Control |

|

Where required, PCS provides technical feedback to prevent recurrence, not just repair outcomes.

Adherence to API 682 Standards

Quality and safety are our top priorities. Our repair processes adhere to API 682 (American Petroleum Institute) standards, guaranteeing that your seals are tested to meet the highest industry benchmarks.

Extended Equipment Life

Our services help extend the life of your rotating equipment, ensuring sustained performance and reliability. Repairing seals is a cost-effective alternative to purchasing new ones, allowing you to allocate resources more efficiently.

Experienced Technicians

Our team of skilled technicians brings years of experience and expertise to every repair, delivering top-notch results every time. Our dedicated teams ensure that your equipment is back in operation quickly and effectively, minimizing downtime and maximizing productivity.

Mechanical Seal Repair for Industrial Applications

PCS repairs mechanical seals used across mining, chemical processing, water and wastewater treatment, manufacturing, and power generation environments.

We work with single, cartridge, and specialised seal designs, repairing seals exposed to:

-

Abrasive or corrosive media

-

Elevated pressures and temperatures

-

Continuous or high-duty operation

-

Process fluids requiring controlled containment

Each repair is assessed on application suitability, not just component condition.

Why Correct Mechanical Seal Repair Matters

Incorrect or incomplete seal repairs often result in:

-

Premature seal failure

-

Increased leakage or emissions

-

Higher maintenance frequency

-

Elevated safety and environmental risk

PCS focuses on correct repair standards, ensuring seals return to service capable of supporting:

-

Process containment

-

Operational stability

-

Predictable maintenance intervals

Speak to PCS About Innomag® Pump Applications

If your operation requires leak-free, safety-critical fluid handling, PCS can assist with selecting and supporting the correct Flowserve HPX mag drive pump configuration for your process.

Contact Process Containment Solutions to discuss your application requirements and operating conditions.