Preservation Program

In such high-stakes operations, compromised spares are not an option.

The consequences of using faulty or degraded parts can be catastrophic, leading to irrecoverable losses in production, time, and profits. Even more concerning, equipment failure due to compromised spares can potentially result in serious injuries or fatalities.

We manage the integrity of our clients’ process equipment portfolio providing long term sustainability & plant reliability.

We understand that you have accumulated hundreds of millions of Rands worth of stock, which is essential for maintaining fast turnaround times and minimizing downtime in a volatile plant environment.

Our Preservation Program is dedicated to maintaining the integrity and readiness of your critical spares.

By ensuring that you have the correct, fully functional parts at all times, we help you avoid these dire consequences and keep your plant running smoothly and safely.

Protect your investment, your team, and your productivity with our comprehensive preservation solutions.

A Preservation Program That’s Designed To Safeguard Your Essential Spares

Preservation Against The Following:

Dust, Rust, & Chemical Corrosion

No matter where a plant is located — be it the arid desert regions, tropical climates near the ocean, or remote sites dealing with corrosive materials—dust, rust, and chemical corrosion present significant and often unavoidable challenges.

Physical Damage

Due to space constraints and close proximity, parts are frequently damaged while stored on the shelf.

This damage can be both costly and dangerous, especially considering these parts may be used in highly volatile applications.

Loss

Not all critical spares are large, singular items; many consist of small, multiple parts that can easily go missing or become separated from the primary components.

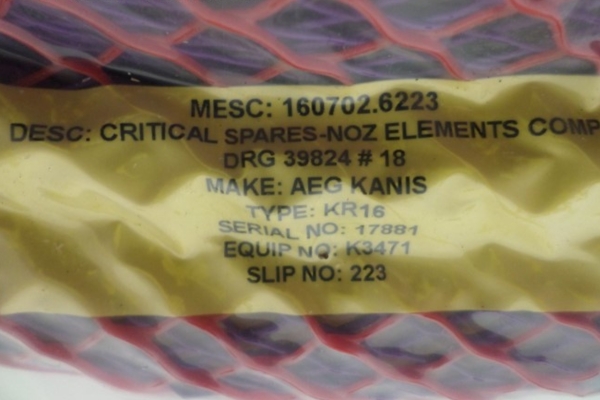

Unidentified Parts

It is common to find parts placed in the wrong bin location without any identification.

Although a user might realise that a part is incorrect for a specific job, they often won’t know what the part is or where it should be properly allocated.

Why Choose PCS For Your Preservation Needs?

- We have all the equipment, parts, raw material and personnel ready to start your project.

- We do all our work “in-house”- nothing is outsourced to a third party.

- Two years of trials, research and development have perfected our technique to ensure items are preserved to ensure maximum shelf life.

- We only use the highest quality raw materials.

- All final, ‘packaged and ready orders’ are kept for 24 hours, and then checked again to ensure “seal integrity”, before being delivered to the customer.

- We preserve each item for less than 5% of its value (and in some instances for much less)

- Our preservation process does not limit us to repairing only mechanical rotating equipment.

- Our labels are clearly marked, and specifically installed in such a way, as to not be damaged, fall off, or fade away.

Contact Our Team Today, Let’s Discuss How We Can Assist You

Why Choose PCS For Your Preservation Needs?

- We have all the equipment, parts, raw material and personnel ready to start your project.

- We do all our work “in-house”- nothing is outsourced to a third party.

- Two years of trials, research and development have perfected our technique to ensure items are preserved to ensure maximum shelf life.

- We only use the highest quality raw materials.

- All final, ‘packaged and ready orders’ are kept for 24 hours, and then checked again to ensure “seal integrity”, before being delivered to the customer.

- We preserve each item for less than 5% of its value (and in some instances for much less)

- Our preservation process does not limit us to repairing only mechanical rotating equipment.

- Our labels are clearly marked, and specifically installed in such a way, as to not be damaged, fall off, or fade away.