Innomag Pumps for Chemical Processing Applications

Pump technology for difficult-to-seal chemical applications.

Designed for the safe handling of toxic, aggressive and flammable liquids in demanding chemical processes, eliminating the need for mechanical seals and external flushing systems while improving reliability and reducing the risk of leakage in critical applications.

An Industry-Leading Solution Engineered For Superior Performance & Reliability.

With a focus on precision and durability, the Flowserve INNOMAG pump is the definitive choice for applications where performance, safety, and environmental compliance are paramount. Designed with cutting-edge technology, this thrust-balanced, fluoropolymer-lined magnetic drive pump delivers exceptional efficiency, even in the harshest and most corrosive environments. Its dynamic thrust balancing system ensures optimal operation without the need for thrust bearings, reducing maintenance and maximizing uptime.

Key Design Features of Innomag® Pumps

Flowserve Innomag pumps are engineered around proven magnetic drive technology and corrosion-resistant materials, delivering consistent performance in demanding operating conditions.

Core design features include:

-

Seal-less magnetic drive configuration (no mechanical seals)

-

Non-metallic, corrosion-resistant pump construction

-

Close-coupled and long-coupled configurations available

-

Hydraulically efficient centrifugal pump design

-

Low vibration and quiet operation

-

Reduced maintenance intervention compared to sealed pumps

Each Innomag pump is specified based on fluid chemistry, temperature, pressure, and duty point to ensure long-term reliability.

Typical Applications for Flowserve Innomag Pumps

Innomag pumps are commonly applied in processes where leakage prevention and chemical compatibility are essential.

| Application Area | Typical Use Case |

|---|---|

| Chemical Transfer & Circulation | Continuous movement of corrosive or hazardous process fluids where leakage prevention is critical. |

| Acid & Caustic Handling | Transfer of aggressive acids and alkalis requiring corrosion-resistant, seal-less pump design. |

| Hazardous & Toxic Fluids | Containment-focused pumping of fluids that pose environmental or personnel safety risks. |

| Water & Wastewater Treatment Chemicals | Dosing and circulation of treatment chemicals with consistent flow and minimal maintenance. |

| Petrochemical & Refinery Systems | Auxiliary services supporting process units where operational reliability is essential. |

| Industrial Process Fluids | General process transfer requiring leak-free operation and material compatibility. |

PCS evaluates each application to confirm suitability, avoiding common issues such as off-design operation, material incompatibility, or thermal overload that can compromise pump performance and lifecycle reliability.

Benefits of Seal-less Innomag® Technology

Selecting a magnetic drive pump is a risk-management decision, not just a product choice.

Operational benefits include:

-

Elimination of seal leakage risk

-

Improved process safety and environmental protection

-

Reduced maintenance and seal replacement costs

-

Lower total cost of ownership over the pump lifecycle

-

Improved uptime in continuous operation systems

These benefits are most effective when the pump is correctly sized and specified for the duty conditions.

PCS Technical Support for Flowserve Innomag Pumps

PCS provides local technical support across South Africa, supporting both new installations and existing Innomag pump systems.

Support services include:

-

Application and pump selection assistance

-

System evaluation and duty verification

-

Genuine spares supply

-

Maintenance and repair support

-

Technical consultation for system optimisation

PCS does not promote one-size-fits-all solutions. Each Innomag pump is selected and supported based on actual operating conditions and risk profile.

Flowserve Innomag Pumps in South Africa

PCS works closely with Flowserve product platforms to support industrial operators, engineering teams, and maintenance managers seeking reliable, containment-focused pumping solutions.

If your process involves hazardous, corrosive, or safety-critical fluids, Flowserve Innomag pumps offer a proven, seal-less solution when correctly specified and supported.

Features & Benefits

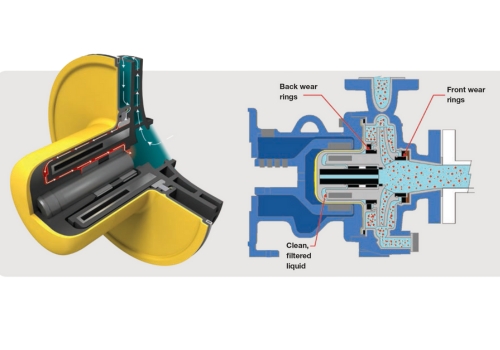

Engineered for precision, the INNOMAG TB-MAG Pump features back wear rings designed to manage solids effectively, ensuring only clean fluid reaches the shaft and bearings, enhancing cooling and longevity.

Flowserve ® INNOMAG TB-MAG. ISO 2858. ASME B73.3

Dynamic Thrust Balancing System

Removes the need for thrust bearings, enhancing efficiency and reliability while minimizing operational costs.

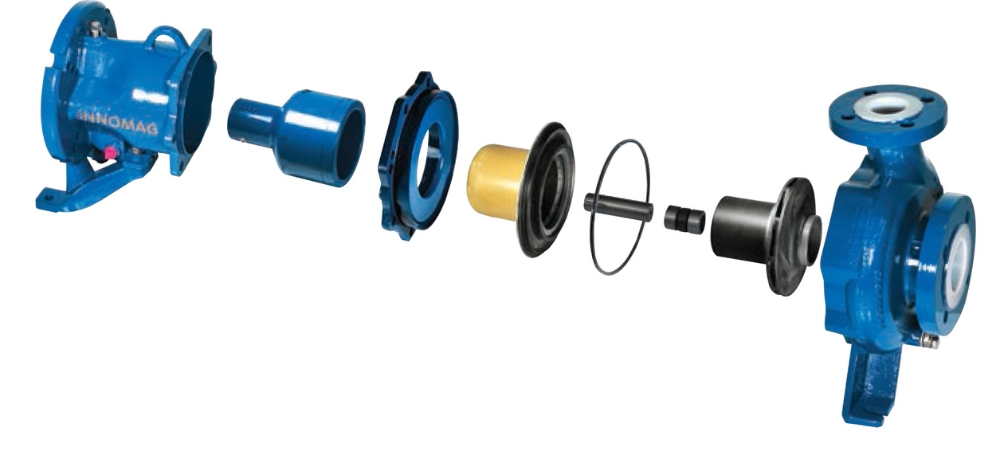

Pure ETFE Casing Liner

Vacuum-rated and features a minimum thickness of 3 mm for optimal durability.

Integrated ETFE Impeller & Magnet Assembly

Maximizes torque, simplifies maintenance, and eliminates balancing requirements.

Enclosed Impeller

Designed with an unobstructed eye for high efficiency and low NPSHR.

Double-sealed Inner Magnets

Encased in 316L stainless steel to resist corrosion and enhance durability.

Composite Containment Shell

Constructed with aramid and carbon fiber-reinforced ETFE for superior leakage prevention and corrosion resistance.

Eddy Current-free Composite Design

Ensures maximum operational efficiency.

Ensures Maximum Operational Efficiency

Oversized to manage radial loads, optimising flow and reducing NPSHR.

Parts Interchangeability

Across sizes to lower inventory costs and streamline maintenance.

Exceptional Solid Handling

Capable of efficiently processing up to 30% solid content of 0.13 mm.

Offering A Cutting-Edge Thrust-Balanced Design

Utilising a dynamic thrust balancing system, it eliminates the need for traditional thrust bearings, enhancing pump reliability and extending its lifespan compared to conventional forward thrust designs.

This innovative approach boosts overall pump efficiency, leading to reduced operational costs and greater long-term performance.

Enhanced Solids-Handling Capability

In magnetic drive pumps, solids can cause damage to radial bearings, inner magnets, and the containment shell. The TB-MAG pump addresses this by utilising silicon carbide back wear rings that block solids larger than 0.127 mm (0.005 in) from entering the containment area.

This ensures that only clean fluid reaches the pump shaft and bearings, preserving their integrity and performance.

Speak to PCS About Innomag® Pump Applications

If your operation requires leak-free, safety-critical fluid handling, PCS can assist with selecting and supporting the correct Flowserve HPX mag drive pump configuration for your process.

Contact Process Containment Solutions to discuss your application requirements and operating conditions.