HPX Mag Drive Process Pumps

Sealless magnetic drive technology for zero-leakage chemical processing.

Engineerd to meet API 685 Standards. Designed for toxic, corrosive, and difficult-to-seal fluids where containment, reliability, and environmental compliance are critical.

Advanced Sealless Pump Technology With Flowserve.

Flowserve HPX™ mag drive process pumps are engineered for applications where leak-free operation, chemical compatibility, and process safety are critical. These sealless centrifugal pumps eliminate the risk of mechanical seal failure, making them well suited to hazardous, toxic, flammable, and environmentally sensitive fluids.

At Process Containment Solutions (PCS), HPX mag drive pumps are specified, supplied, and supported based on actual process conditions, ensuring reliable operation and long-term lifecycle performance in demanding industrial environments across South Africa.

Key Design Features

The seal-less configuration and materials selection support zero external leakage, regulatory adherence, and consistent operation within defined design limits.

- Sealless magnetic drive construction for zero external leakage

-

ANSI dimensional compliance for straightforward system integration

-

High-integrity containment shell for hazardous fluids

-

Optimised hydraulic design for stable, predictable operation

-

Materials engineered for corrosion resistance, depending on process media

-

Low-maintenance configuration with reduced wear components

Each HPX pump configuration is selected to align with duty point, fluid properties, temperature, and operating pressure.

What is an HPX Mag Drive Process Pump?

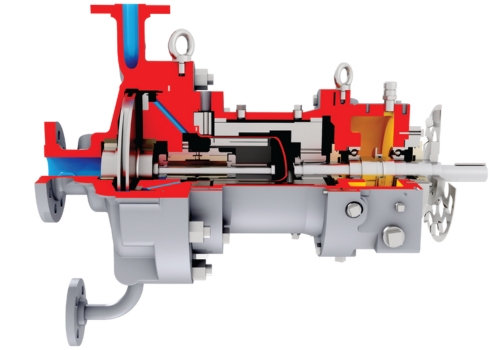

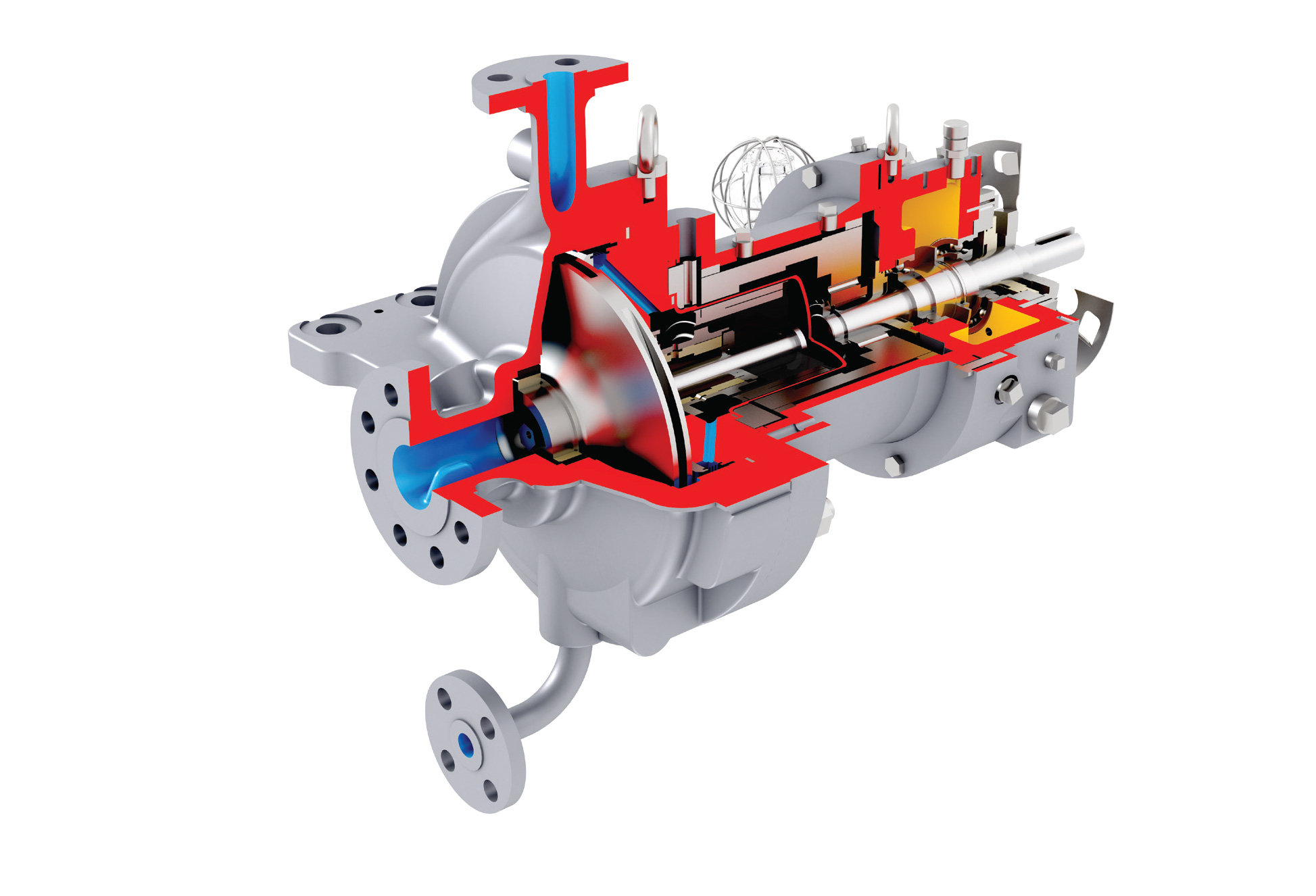

The HPX mag drive pump uses a magnetic coupling to transmit torque from the motor to the impeller, removing the need for a dynamic shaft seal. The pump’s containment shell forms a sealed barrier between the process fluid and the atmosphere.

This design significantly reduces:

-

Fugitive emissions

-

Environmental exposure

-

Unplanned downtime related to seal failure

HPX pumps are designed to meet the requirements of ISO and ANSI process pump standards, supporting consistent performance in chemical and petrochemical services.

Application and Materials Configuration for HPX Mag Drive Pumps

Flowserve HPX Mag Drive Process Pumps are specified for applications where leak-free operation, chemical compatibility, and controlled performance are critical. Correct application and material selection is essential to support safe containment and long-tem lifecycle reliability.

| Typical Applications | Materials & Configuration Options |

|---|---|

|

Flowserve HPX mag drive pumps are commonly used in:

PCS evaluates each application to confirm that the HPX pump’s hydraulic design, materials, and magnetic coupling limits are suitable for the intended service. |

HPX mag drive pumps are available in a range of materials and configurations, including:

PCS assists with materials compatibility assessment to minimise corrosion, erosion, and internal wear. |

Advantages of HPX Mag Drive Pumps in Industrial Systems

Flowserve HPX magnetic drive pumps are designed for zero-leakage operation in regulated and hazardous process environments.

By eliminating dynamic seals and fully containing the process fluid, the HPX supports compliance requirements while reducing emission risk, safety exposure, and unplanned maintenance in continuous-duty industrial systems.

- Eliminates mechanical seal-related failures

- Improves plant safety in hazardous fluid applications

- Reduces environmental and compliance risk

- Lowers total cost of ownership through reduced maintenance

- Provides consistent performance under continuous-duty conditions

Correct selection is essential. Oversizing, incorrect materials, or operating outside design limits can compromise reliability and internal component life.

| Hydraulic & Containment Features | Reliability & Maintenance Features |

|---|---|

|

Internal Flushing High-torque Magnets Backup Renewable Rings Centerline-supported Pump Casting Precision Cast Impeller |

Leakage-free Containment Shell Lubricated Radial & Thrust Bearings Consolidated Hydraulic Design Back Pullout Design |

Local Technical Support in South Africa

PCS provides local technical support for Flowserve HPX mag drive process pumps across South Africa, supporting both new installations and existing pump systems.

Support capabilities include:

-

Application and pump selection assistance

-

Spares identification and supply

-

Inspection, maintenance, and repair support

-

Troubleshooting and performance optimisation

-

Technical consultation aligned with plant operating conditions

Local support ensures faster response times, reduced operational risk, and continuity in critical chemical processing operations.

Speak to PCS About HPX Mag Drive Pumps

If your operation requires leak-free, safety-critical fluid handling, PCS can assist with selecting and supporting the correct Flowserve HPX mag drive pump configuration for your process.

Contact Process Containment Solutions to discuss your application requirements and operating conditions.